Industrial 3D Printing — The Future of Smart Production and 3D Manufacturing UAE

Introduction

The manufacturing world is evolving — and additive manufacturing is leading the transformation. Across the Middle East, businesses are embracing industrial 3D printing to accelerate production, improve product performance, and reduce costs.

At Ultratec 3D, we specialize in 3D manufacturing UAE — providing end-to-end additive manufacturing solutions for industries that demand precision, quality, and scalability.

From functional prototypes to full-scale production parts, we deliver next-generation manufacturing powered by innovation and technology.

What Is Industrial 3D Printing?

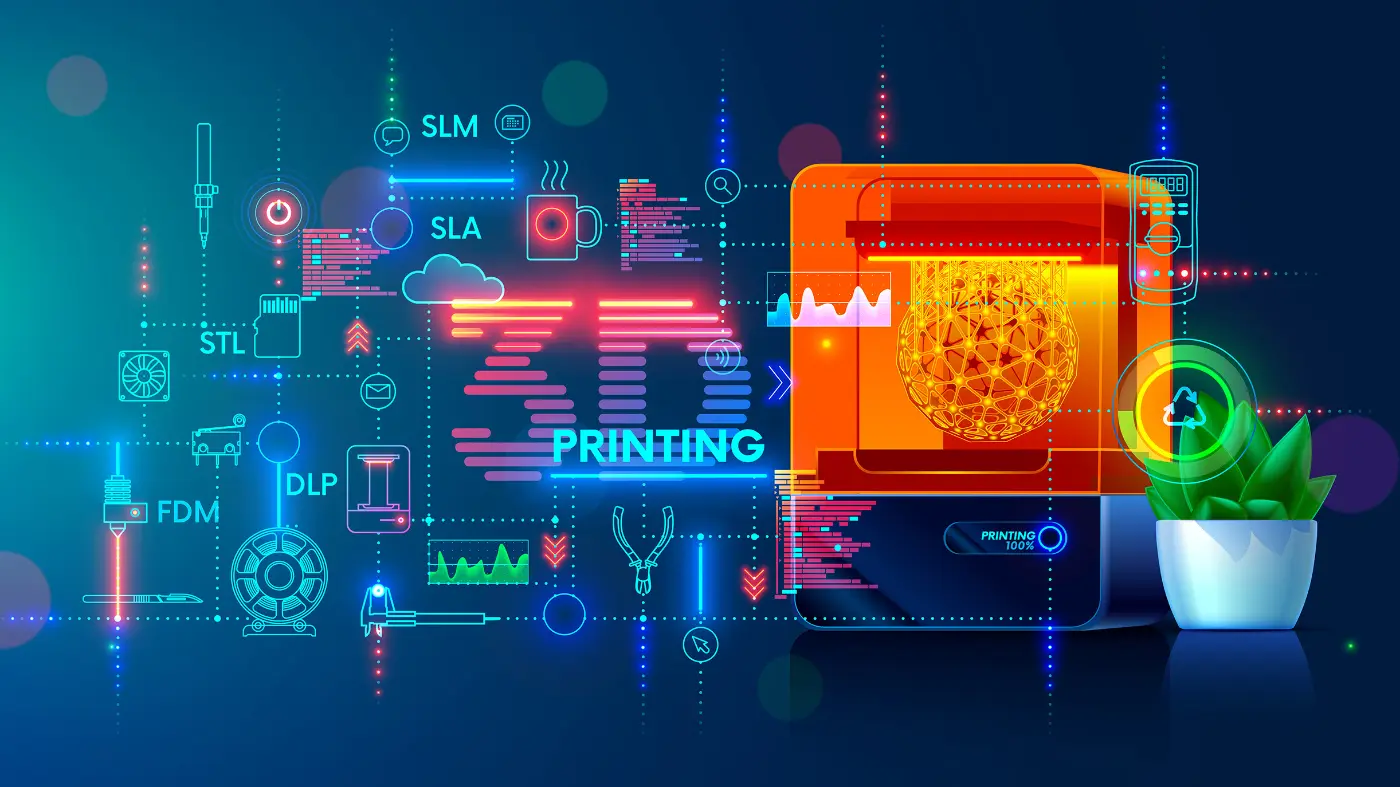

Industrial 3D printing — also known as additive manufacturing — is a production method that creates parts layer by layer using digital design data. Unlike traditional machining or molding, it enables complex geometries, faster turnaround, and minimal waste.

Benefits of Industrial 3D Printing:

- Design freedom: Create complex internal structures and custom geometries.

- Speed: Shorten production lead times by up to 70%.

- Cost efficiency: Reduce tooling and setup costs.

- Sustainability: Lower material waste and energy use.

- Flexibility: Manufacture on demand — from one piece to thousands.

With advanced materials and high-precision equipment, Ultratec 3D delivers industrial-grade quality across all applications.

3D Manufacturing UAE — Building the Future Locally

The UAE is rapidly becoming a hub for advanced manufacturing, driven by government initiatives like Dubai 3D Printing Strategy and Industry 4.0 programs.

As part of this transformation, Ultratec 3D offers 3D manufacturing UAE services that support local industries — providing rapid prototyping, tooling, and production-ready components with unmatched precision.

Key Industries We Serve:

- Automotive & Aerospace: Lightweight components and performance parts.

- Architecture & Construction: Scaled models and structural prototypes.

- Medical & Dental: Custom implants, models, and surgical tools.

- Industrial Equipment: Functional parts and replacement components.

- Education & Research: Academic prototypes and innovation projects.

We bridge the gap between concept and production, helping companies in the UAE innovate faster and manufacture smarter.

How Ultratec 3D Delivers Excellence

As a pioneer in industrial 3D printing and 3D manufacturing UAE, Ultratec 3D provides a complete ecosystem of design, engineering, and manufacturing services.

Our Capabilities Include:

- Multi-technology 3D printing: FDM, SLA, SLS, DLP, and metal additive systems

- Design for Additive Manufacturing (DfAM) and engineering optimization

- High-performance materials: polymers, composites, resins, and metals

- Post-processing, finishing, and quality assurance

- Full-scale batch production for industrial applications

By combining expertise with technology, we ensure every part we produce meets the highest global standards.

From Design to Production — Our Workflow

- Consultation & Design Analysis: Understand your product and performance goals.

- 3D Modeling & Simulation: Prepare optimized CAD designs for printing.

- Material Selection: Choose the best-fit materials for strength, durability, and function.

- Printing & Manufacturing: Use advanced 3D printers for consistent, high-accuracy results.

- Post-Processing & Testing: Ensure perfect finish and quality compliance.

- Delivery & Support: Deliver production-ready components within days.

This streamlined process ensures speed, reliability, and total control — from prototype to mass production.

Why Choose Ultratec 3D

- Comprehensive Solutions: From design to end-use parts, all under one roof.

- Industrial-Grade Equipment: High-precision additive manufacturing systems.

- Expert Engineering Team: Specialists in mechanical, aerospace, and product design.

- Material Expertise: Access to a wide range of advanced polymers and composites.

- UAE-Based Operations: Fast turnaround and local support for all GCC clients.

At Ultratec 3D, we don’t just print parts — we engineer complete manufacturing solutions.

Applications of Industrial 3D Printing

- Functional Prototypes: Validate designs before full production.

- Tooling & Fixtures: Replace expensive CNC tooling with fast, accurate 3D-printed alternatives.

- End-Use Parts: Durable, lightweight components for machinery or production lines.

- Customization: Tailored designs for specific industrial needs.

- Maintenance Parts: On-demand replacement for obsolete components.

Our industrial 3D printing systems support low-to-medium production runs, bridging the gap between prototyping and mass manufacturing.

FAQs

1. What’s the difference between prototyping and industrial 3D printing?

Prototyping is for design testing; industrial 3D printing produces final-use components that meet performance standards.

2. Can 3D-printed parts replace traditional manufacturing?

Yes — for many industries, 3D manufacturing UAE provides a faster, more flexible, and cost-effective alternative.

3. What materials do you use for industrial parts?

We print with engineering-grade polymers, resins, metals, and composites.

4. Is Ultratec 3D suitable for large-scale production?

Absolutely. We offer both rapid prototyping and scalable additive manufacturing solutions.

5. Do you provide design and engineering support?

Yes — our in-house team assists from concept development to final production.

Final Thoughts

Industrial 3D printing is no longer a future concept — it’s transforming how industries operate today. With 3D manufacturing UAE, companies can now design, test, and produce faster than ever before, right here in the region.