IP Ratings and Environmental Resistance of M12 Connectors

M12 connectors are widely used in industrial automation, factory control systems, robotics, and other demanding applications due to their compact size, robust construction, and versatility. One of the critical factors that make M12 connectors reliable in harsh industrial environments is their ability to resist dust, water, and other environmental hazards. This protection is measured through IP (Ingress Protection) ratings, which define the level of resistance provided by the connector’s housing and sealing components. Understanding IP ratings and environmental resistance is essential for engineers and system designers when selecting the appropriate M12 connector for specific industrial applications.

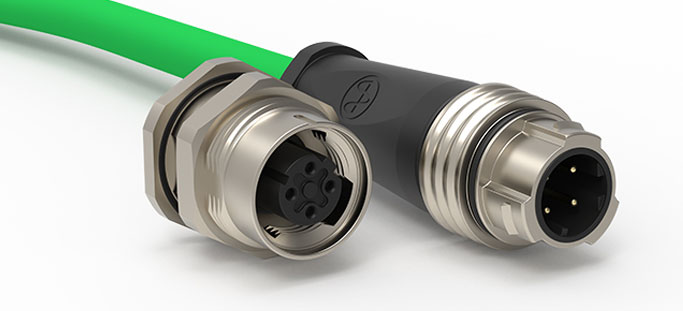

The M12 Connector is designed to withstand challenging conditions such as vibration, moisture, dust, and temperature extremes. Its standardized design, threaded coupling, and sealing mechanisms allow it to maintain electrical and mechanical performance in demanding environments. By evaluating IP ratings and environmental resistance, engineers can ensure reliable connectivity, reduce maintenance issues, and improve system longevity.

Understanding IP Ratings

IP ratings are defined by the international standard IEC 60529, which classifies the degree of protection provided by electrical enclosures against the ingress of solid particles and liquids. The IP rating typically consists of two digits:

- First Digit (Solid Particle Protection): Indicates protection against solid objects, such as dust or debris. Ratings range from 0 (no protection) to 6 (dust-tight).

- Second Digit (Liquid Protection): Indicates protection against water or other liquids. Ratings range from 0 (no protection) to 9K (protection against high-pressure, high-temperature water jets).

For M12 connectors, the most common IP ratings are IP65, IP67, and IP68. These ratings are essential for industrial environments, where exposure to dust, water, or chemicals can affect connector performance and lead to system failures.

Common IP Ratings for M12 Connectors

IP65

An IP65-rated M12 connector is fully protected against dust and low-pressure water jets from any direction. This rating is suitable for indoor industrial environments, such as factory floors or control panels, where occasional exposure to dust or cleaning sprays may occur. IP65 connectors are widely used for sensor and actuator connections where moderate environmental protection is sufficient.

IP67

IP67-rated M12 connectors provide the same dust protection as IP65 but are also capable of withstanding temporary immersion in water, typically up to one meter for 30 minutes. This level of protection is ideal for outdoor applications, wet industrial environments, and locations subject to accidental splashes or flooding. IP67 connectors are commonly used in robotics, food processing, and conveyor systems, where moisture exposure is frequent.

IP68

IP68-rated M12 connectors offer the highest level of environmental protection, ensuring dust-tight performance and continuous immersion in water beyond one meter, as specified by the manufacturer. These connectors are designed for extreme conditions, such as outdoor installations, irrigation systems, or industrial machinery exposed to harsh weather. IP68-rated connectors provide long-term reliability in environments where other connectors might fail due to moisture ingress.

Environmental Resistance Features

The environmental resistance of M12 connectors is not limited to IP ratings. Several design features contribute to their ability to withstand harsh conditions:

- Threaded Coupling: M12 connectors use an M12 threaded coupling to secure the connection, preventing accidental disconnection due to vibration or mechanical stress.

- Sealing Elements: O-rings, gaskets, and precision-molded seals prevent dust, water, and chemical ingress, ensuring long-term electrical reliability.

- Housing Materials: Metal housings, such as nickel-plated brass or stainless steel, provide mechanical strength and corrosion resistance. High-performance plastics, such as PBT, offer chemical resistance, impact resistance, and lighter weight.

- Temperature Tolerance: M12 connectors are designed to operate reliably across wide temperature ranges, typically from -40°C to 125°C, ensuring performance in both hot and cold industrial environments.

Applications Requiring High Environmental Resistance

M12 connectors with high IP ratings are used in applications that demand robust environmental protection:

- Outdoor Automation Systems: IP67 or IP68-rated M12 connectors are used in outdoor machinery, agricultural equipment, and irrigation systems.

- Robotics and Conveyor Systems: Frequent exposure to water, dust, and vibration makes IP65 and IP67-rated connectors ideal for industrial robots and automated material handling systems.

- Food and Beverage Industry: Connectors resistant to cleaning chemicals and moisture ensure safe operation in food processing plants.

- Transportation and Automotive Applications: IP-rated M12 connectors are used in vehicles, trains, and other mobile equipment that encounter water, dust, and temperature fluctuations.

Advantages of Using IP-Rated M12 Connectors

Selecting M12 connectors with appropriate IP ratings and environmental resistance provides several benefits:

- Reliable Performance: Maintains electrical and mechanical integrity under challenging conditions.

- Reduced Downtime: Prevents failures caused by dust, water, or corrosion, minimizing maintenance and repair requirements.

- Safety: Reduces the risk of short circuits, equipment damage, and operational hazards.

- Versatility: Suitable for a wide range of industrial applications, from indoor automation to outdoor equipment.

Conclusion

IP ratings and environmental resistance are crucial factors when selecting M12 connectors for industrial applications. By understanding the level of protection provided by IP65, IP67, and IP68-rated connectors, engineers can ensure reliable operation in dust, moisture, and chemical-prone environments. Coupled with robust mechanical design, threaded coupling, and high-quality housing materials, M12 connectors provide secure, long-lasting connections in demanding industrial settings. Selecting the appropriate IP-rated M12 connector enhances system reliability, reduces maintenance costs, and ensures the safe and efficient operation of industrial equipment.