What Is Insulation Duct Board and How Is It Used?

In modern HVAC systems, maintaining energy efficiency and indoor air quality is essential. One of the key components contributing to these goals is insulation duct board. This material serves as both a structural element and a thermal barrier within duct systems, helping to optimize performance while reducing energy loss. Understanding what insulation duct board is, its composition, and its applications is critical for HVAC engineers, contractors, and facility managers seeking reliable and efficient ductwork solutions.

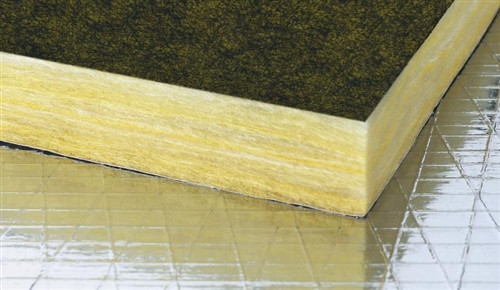

Insulation duct board is a rigid panel made from mineral fibers, fiberglass, or other specialized insulating materials. It is designed to provide both thermal insulation and acoustic dampening within HVAC systems. Unlike flexible duct liners, which are applied to the interior of metal ducts, insulation duct boards form the actual walls of ductwork in some systems, particularly in custom-fabricated or pre-insulated ducts. By offering structural support and insulation in a single material, these boards simplify fabrication and installation processes. Leading manufacturers provide high-quality insulation duct board products that meet industry standards for fire resistance, thermal performance, and durability, making them suitable for a wide range of residential, commercial, and industrial applications.

Composition and Types of Insulation Duct Board

Insulation duct boards are primarily made from mineral wool or fiberglass. Mineral wool boards are derived from natural rock or slag fibers and are known for their excellent thermal resistance, fireproof qualities, and sound absorption. Fiberglass boards consist of glass fibers bound together with a resin, offering high insulation performance and lightweight construction. Some duct boards also include a foil or plastic facing, which acts as a vapor barrier and provides additional moisture protection.

These boards come in various thicknesses, densities, and sizes, allowing HVAC professionals to select the right material for specific applications. Thicker, denser boards are often used in environments requiring superior acoustic performance or higher thermal resistance, while lighter boards are suitable for standard air distribution systems.

Applications in HVAC Systems

Insulation duct boards are widely used in the fabrication of HVAC ductwork, particularly in rectangular and custom-shaped ducts. They are ideal for creating rigid ducts for air distribution systems, offering both structural support and thermal insulation. By forming the duct walls from insulated panels, energy loss during heating or cooling is significantly reduced, leading to more efficient operation of HVAC systems.

Another important application of insulation duct boards is in noise reduction. The dense, fibrous structure absorbs sound generated by air movement, fans, and mechanical equipment, minimizing transmission to occupied spaces. This acoustic benefit makes duct boards a preferred choice in offices, hospitals, schools, and other environments where noise control is essential.

Fabrication and Installation

Fabricating ducts from insulation duct board typically involves cutting panels to size, joining them using adhesives or mechanical fasteners, and sealing seams with appropriate tapes or mastics to prevent air leakage. Panels can be cut using standard woodworking tools, although specialized cutting equipment can improve accuracy and efficiency. In larger workshops or production facilities, automated cutting and fabrication machines are often used to streamline the process and ensure precise dimensions.

During installation, insulation duct boards are supported by framing or mounted directly within HVAC systems. Proper sealing at joints and connections is critical to maintain thermal performance and prevent leakage. Some systems may include a protective outer jacket or facing for additional durability, moisture resistance, and fire protection.

Advantages of Using Insulation Duct Board

The use of insulation duct board in HVAC systems provides several advantages:

1. Improved Energy Efficiency: By providing continuous thermal insulation, duct boards reduce heat loss or gain, helping HVAC systems maintain desired indoor temperatures while consuming less energy.

2. Acoustic Performance: The fibrous composition absorbs sound, reducing noise transmission and creating a quieter indoor environment.

3. Fire Resistance: Mineral wool-based duct boards are inherently fire-resistant, enhancing the safety of ductwork in commercial and industrial buildings.

4. Lightweight and Easy to Fabricate: Despite their structural integrity, insulation duct boards are relatively lightweight, making cutting, handling, and installation simpler compared to metal ducts with separate insulation.

5. Versatility: They are suitable for various applications, from standard air distribution to custom-shaped duct systems and pre-insulated solutions.

Maintenance and Longevity

Insulation duct boards are durable and require minimal maintenance. Regular inspections should focus on checking for damage, moisture intrusion, or compromised seams. Proper installation and sealing ensure long-term thermal performance, while maintaining the integrity of the board contributes to both energy efficiency and indoor air quality.

Conclusion

Insulation duct board is a versatile and essential material in modern HVAC systems, combining thermal insulation, acoustic dampening, and structural support in a single panel. Its use in duct fabrication improves energy efficiency, reduces noise, and enhances fire safety, making it a reliable solution for a wide range of applications. By understanding its composition, advantages, and installation methods, HVAC professionals can effectively integrate insulation duct board into their systems, ensuring optimal performance and long-term durability.