How Investment Casting Produces High-Precision Metal Components

In modern manufacturing, producing metal components with complex geometries and high precision is essential across industries such as aerospace, automotive, and medical equipment. One of the most reliable and versatile methods for achieving these results is Investment Casting, a process that combines precision, flexibility, and efficiency to create high-quality metal parts.

By using Investment Casting, manufacturers can produce components with exceptional accuracy and fine surface finishes. This process involves creating a detailed wax model, forming a ceramic mold around it, and then casting molten metal into the mold. The resulting metal parts closely replicate the original wax pattern, making investment casting ideal for applications where tight tolerances and intricate designs are required.

The Investment Casting Process

1. Creating the Wax Pattern

The process begins with the creation of a wax model, which is an exact replica of the final component. These wax patterns can be produced individually or as part of an assembly called a “tree,” which allows multiple parts to be cast simultaneously. High precision in the wax pattern is critical because it determines the accuracy of the final metal part.

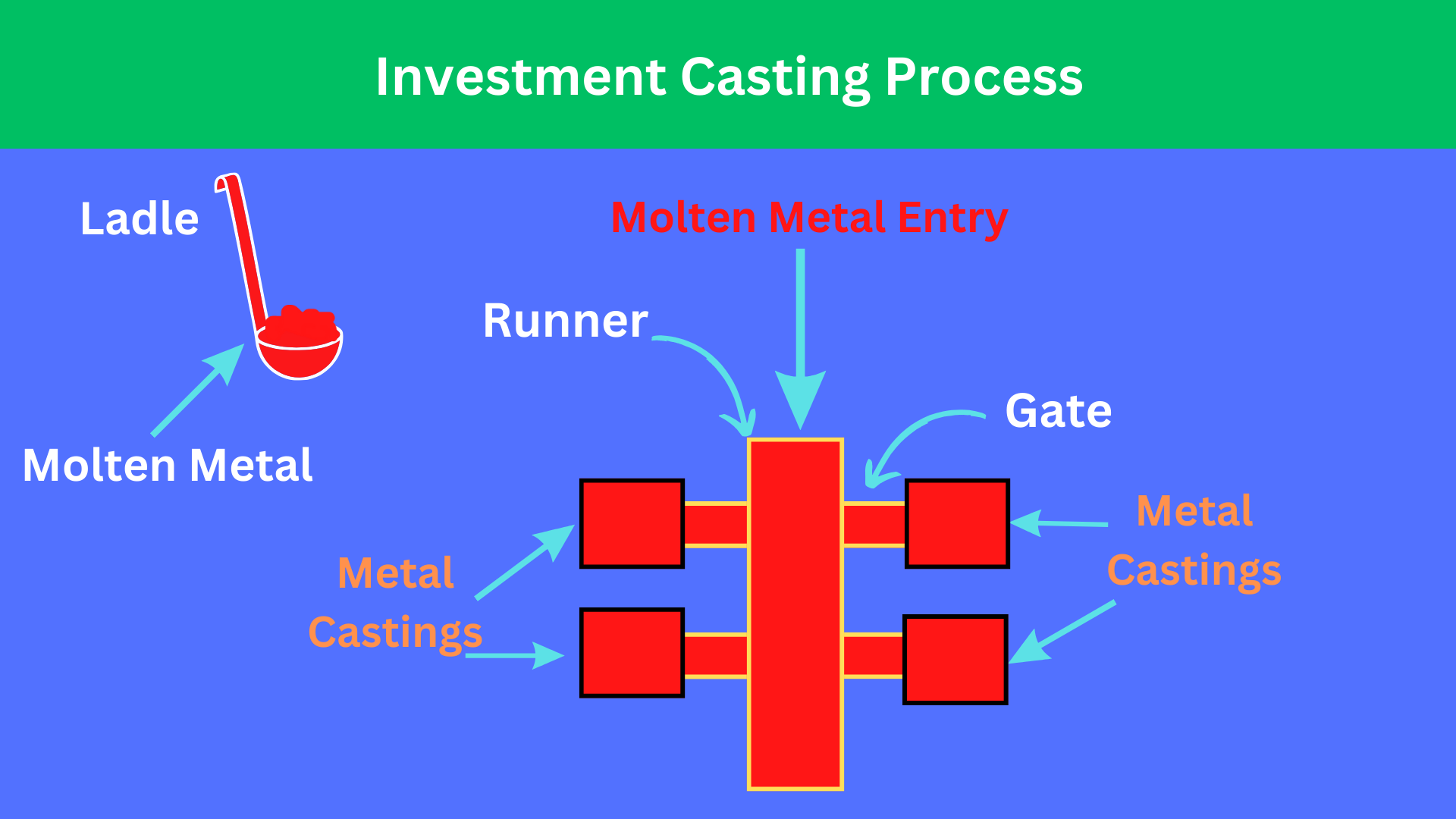

2. Assembly and Spruing

Wax patterns are assembled onto a central wax sprue to form a tree-like structure. The sprue system provides channels for molten metal to flow into the mold during casting. This step ensures proper metal distribution and reduces the risk of defects in the final components.

3. Ceramic Shell Building

The wax assembly is repeatedly dipped into a ceramic slurry and coated with fine refractory materials. Each layer is allowed to dry before the next is applied. This process continues until a thick, durable ceramic shell forms around the wax pattern, which will serve as the mold for casting.

4. Wax Removal

Once the ceramic shell is complete, the assembly is heated in an autoclave or furnace to melt and remove the wax. This leaves a hollow cavity in the shape of the original wax pattern. This step is crucial for maintaining the precision of the mold and ensuring that intricate details are preserved.

5. Metal Pouring

Molten metal is poured into the ceramic mold under controlled conditions. The metal fills the cavity, capturing the fine details and complex geometries of the wax pattern. Investment casting is compatible with a wide range of metals and alloys, including stainless steel, aluminum, and titanium, allowing for tailored mechanical properties.

6. Cooling and Shell Removal

After the metal has solidified and cooled, the ceramic shell is broken away, revealing the rough metal casting. This process is called “knockout.” The result is a high-precision metal component that closely matches the original wax pattern.

7. Finishing and Inspection

The final step involves removing any sprues, gates, or excess material and performing finishing operations such as grinding, machining, or polishing. Each part undergoes rigorous inspection to ensure dimensional accuracy, surface quality, and structural integrity.

Applications of Investment Casting

Investment casting is widely used in industries that require precision and reliability.

- Aerospace: Produces turbine blades, engine components, and structural parts with complex geometries and high strength.

- Automotive: Used for engine components, transmission parts, and custom alloy pieces requiring tight tolerances.

- Medical Equipment: Manufactures surgical instruments, orthopedic implants, and other high-precision medical devices.

- Industrial Machinery: Creates gears, pumps, valves, and other components that must withstand high stress and wear.

Advantages of Investment Casting

- High Precision: Captures intricate details and tight tolerances.

- Smooth Surface Finish: Reduces the need for extensive post-processing.

- Material Flexibility: Works with a wide range of metals and alloys.

- Complex Geometries: Enables production of parts that are difficult or impossible with other casting methods.

- Efficiency: Produces multiple components in a single mold assembly, reducing production costs.

Conclusion

Investment Casting is a highly effective manufacturing process for producing complex, high-precision metal components. By using wax patterns and ceramic molds, manufacturers can achieve exceptional accuracy, fine surface finishes, and intricate designs that meet demanding industrial standards.

For industries that require reliable, high-quality metal parts with tight tolerances, investment casting provides a versatile and efficient solution, supporting both small-scale and high-volume production needs.