How Waterproof Composite Fabric Is Used in Modern Home and Industrial Textiles

The demand for high-performance textiles has increased significantly as both households and industries seek materials that deliver durability, hygiene, and long-term reliability. Traditional fabrics often struggle to meet these expectations, especially in environments exposed to moisture, spills, or harsh conditions. As a result, advanced textile solutions have gained prominence for their ability to combine protection with practicality.

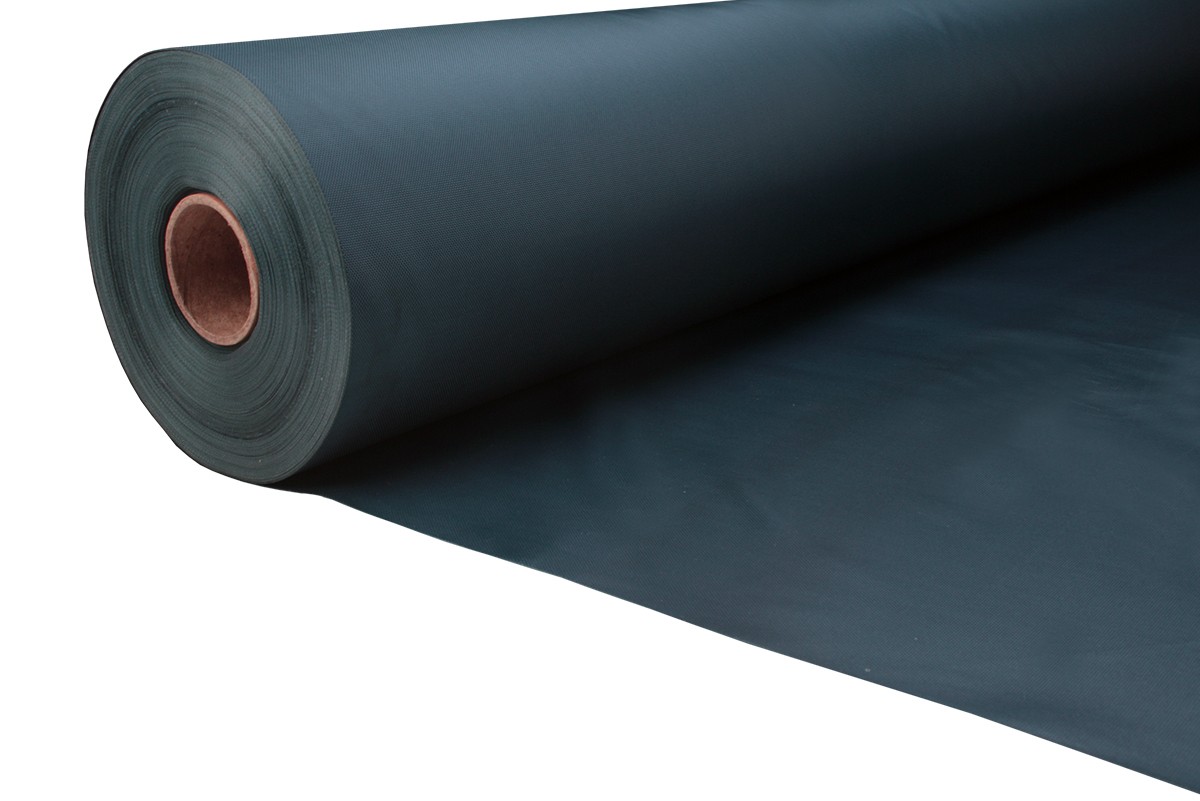

Among these innovations, Waterproof Composite Fabric has become a preferred choice due to its engineered multi-layer structure and consistent performance. By integrating different functional layers into a single textile, this fabric type addresses the limitations of conventional materials and offers reliable waterproofing without sacrificing usability. Its growing adoption reflects the shift toward smarter, application-driven fabric design.

Understanding the Structure of Waterproof Composite Fabric

Waterproof composite fabric is created by bonding multiple layers, each designed to serve a specific function. Typically, the structure includes a protective outer layer, a waterproof membrane in the middle, and a supportive or comfort-focused inner layer. This layered approach allows the fabric to block liquid penetration while maintaining strength, flexibility, and stability.

The bonding process, which may involve lamination or thermal techniques, ensures that the layers act as one unified material. This construction not only enhances performance but also improves resistance to wear, washing, and repeated use, making the fabric suitable for both domestic and industrial environments.

Applications in Modern Home Textiles

In home textiles, waterproof composite fabric plays a crucial role in improving comfort and cleanliness. It is commonly used in mattress protectors, pillow covers, and bed encasements, where moisture resistance helps protect against spills, sweat, and allergens. These applications are particularly valuable in households with children, elderly individuals, or pets.

Furniture upholstery is another area where composite fabrics are widely used. Sofas, chairs, and cushions benefit from the waterproof barrier, which prevents liquids from seeping into the padding while preserving the appearance and feel of the outer surface. This combination of protection and aesthetics has made composite fabrics a popular option in modern interior design.

Role in Healthcare and Hygiene-Focused Settings

Healthcare environments demand textiles that meet strict hygiene and durability standards. Waterproof composite fabrics are extensively used in hospital bedding, medical covers, and protective barriers. Their ability to resist fluid penetration helps reduce contamination risks and supports infection control protocols.

In addition, these fabrics are easy to clean and maintain, which is essential in settings where frequent washing and disinfection are required. The layered construction ensures that repeated laundering does not compromise waterproof performance, making them a reliable choice for long-term use.

Industrial Textile Applications

Beyond the home and healthcare sectors, waterproof composite fabric is widely utilized in industrial textiles. Protective covers for machinery, equipment enclosures, and outdoor storage solutions rely on these materials to shield valuable assets from moisture, dust, and environmental exposure.

In manufacturing and logistics, composite fabrics are also used for packaging and transport covers. Their durability and resistance to tearing provide added security during handling and transit. The adaptability of composite structures allows manufacturers to customize thickness, strength, and flexibility according to specific industrial requirements.

Performance Advantages Across Environments

One of the key reasons for the widespread use of waterproof composite fabric is its consistent performance across different environments. Unlike surface-treated fabrics that lose effectiveness over time, composite materials maintain their waterproof properties throughout their lifespan. This reliability reduces replacement frequency and lowers overall maintenance costs.

Additionally, many composite fabrics are designed to offer breathability, allowing moisture vapor to escape while preventing liquid ingress. This balance is especially important in applications where comfort and condensation control are critical.

Sustainability and Long-Term Value

As sustainability becomes a priority in textile manufacturing, waterproof composite fabrics are evolving to meet environmental expectations. Many modern designs incorporate recyclable components or production methods that minimize waste. The extended lifespan of these fabrics also contributes to sustainability by reducing the need for frequent replacements.

From an economic perspective, the durability and versatility of composite fabrics provide strong long-term value. Although initial costs may be higher than traditional materials, the performance benefits and reduced upkeep often result in lower total ownership costs.

Conclusion

Waterproof composite fabric has become an essential material in modern home and industrial textiles due to its layered construction, reliable performance, and wide-ranging applications. From household bedding and furniture to healthcare and industrial uses, it delivers protection, durability, and practicality in demanding conditions. As textile technology continues to advance, composite fabrics are expected to play an even greater role in shaping functional and sustainable textile solutions.