Industrial Marking Machines: A Guide for Beginners

Industrial marking machines are essential tools in modern manufacturing, enabling businesses to label, identify, and track products efficiently. These machines are widely used across industries such as automotive, electronics, pharmaceuticals, and packaging. For beginners, understanding how industrial marking machines work and the benefits they offer is crucial for making informed decisions when selecting equipment for production lines.

Working with an experienced industrial marking machine manufacturer can help beginners choose the right machine tailored to their production needs. Manufacturers provide expert advice on machine types, marking technologies, and integration options, ensuring smooth operation and optimal efficiency. Partnering with a reputable manufacturer also ensures ongoing support, training, and access to consumables, making the learning process easier for newcomers.

What Are Industrial Marking Machines?

Industrial marking machines are automated systems designed to apply permanent or semi-permanent marks on products. These marks can include serial numbers, batch codes, barcodes, logos, and expiration dates. Unlike manual labeling methods, industrial marking machines offer precision, speed, and consistency, reducing errors and improving overall productivity.

These machines are suitable for a variety of materials, including metals, plastics, glass, and paper. The choice of machine and marking method depends on factors such as the material, production volume, and desired durability of the mark.

Types of Industrial Marking Machines

For beginners, it is important to understand the main types of industrial marking machines:

1. Inkjet Printers:

Inkjet systems, including continuous inkjet (CIJ) and small character printers, spray ink onto the product surface. They are ideal for high-speed production lines and can mark irregular or moving surfaces.

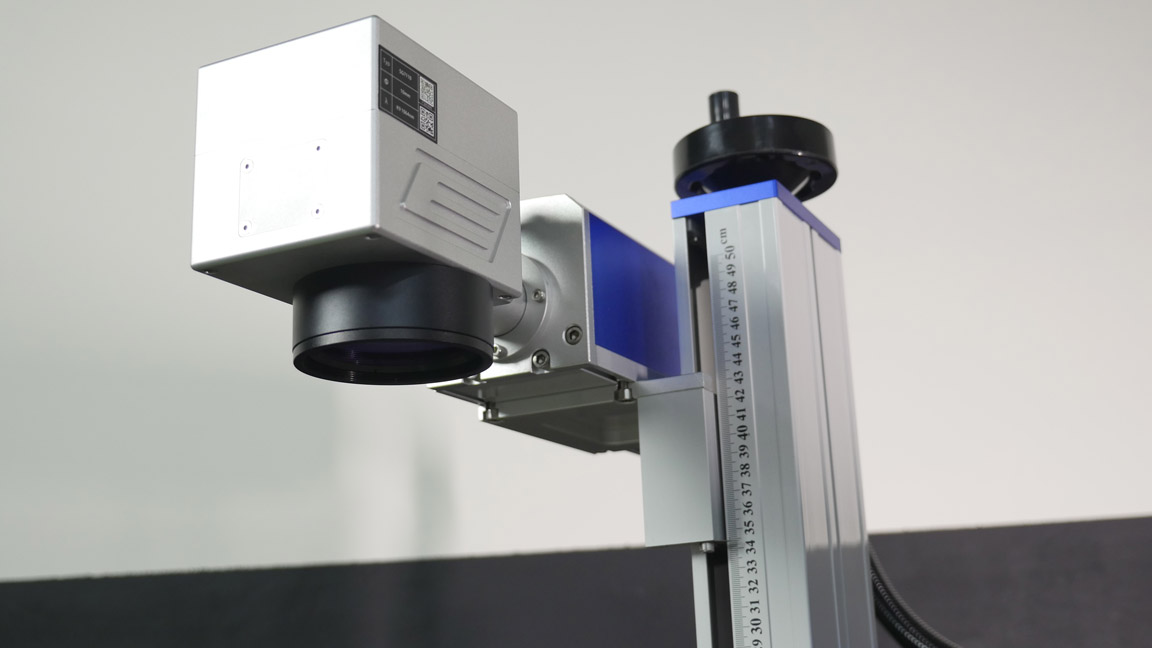

2. Laser Marking Machines:

Laser systems use focused beams of light to etch or engrave permanent marks onto products. They are precise, durable, and low-maintenance, making them suitable for metals, plastics, and glass.

3. Dot Peen Marking Machines:

Dot peen machines create indentations on surfaces by repeatedly striking with a stylus. They are commonly used in heavy-duty applications where permanent and readable marks are required.

4. Thermal Transfer Printers:

These machines use heat to transfer ink from a ribbon to the product surface. Thermal transfer printers are often used for packaging, producing high-resolution text, images, and barcodes.

Benefits of Using Industrial Marking Machines

Industrial marking machines offer several advantages for beginners and established manufacturers alike:

- Increased Efficiency: Automation speeds up the marking process, reducing production time.

- Accuracy and Consistency: Automated systems ensure uniform and legible marks across all products.

- Traceability: Marks such as batch numbers and serial codes improve product tracking throughout the supply chain.

- Compliance: Machines help meet regulatory requirements for labeling in industries such as pharmaceuticals and food production.

- Durability: Marks produced by industrial machines are resistant to abrasion, heat, and chemicals, ensuring long-lasting identification.

Key Considerations for Beginners

When selecting an industrial marking machine, beginners should consider the following:

- Material Compatibility: Choose a machine suitable for the materials used in production.

- Production Volume: Ensure the machine can keep up with your production speed and batch size.

- Marking Requirements: Determine the type, size, and clarity of marks needed for your products.

- Integration: Consider machines that can easily integrate with existing production lines or automation systems.

- Maintenance and Support: Look for machines that are easy to maintain and come with reliable manufacturer support.

Tips for Effective Use

To maximize the benefits of industrial marking machines, beginners should follow these tips:

- Train operators on proper machine use and safety procedures.

- Regularly perform maintenance and replace consumables such as ink or ribbons.

- Test the machine on sample products to ensure mark quality and accuracy.

- Keep software and firmware updated to maintain optimal performance.

Conclusion

Industrial marking machines are invaluable tools for modern manufacturing, offering efficiency, precision, and compliance. For beginners, understanding the types of machines, their benefits, and key selection considerations is essential for making informed decisions. Partnering with a reliable industrial marking machine manufacturer ensures access to expert guidance, proper training, and ongoing support, helping newcomers integrate these machines seamlessly into production lines. By investing in the right equipment and following best practices, beginners can enhance productivity, maintain product quality, and ensure accurate identification and traceability throughout the manufacturing process.