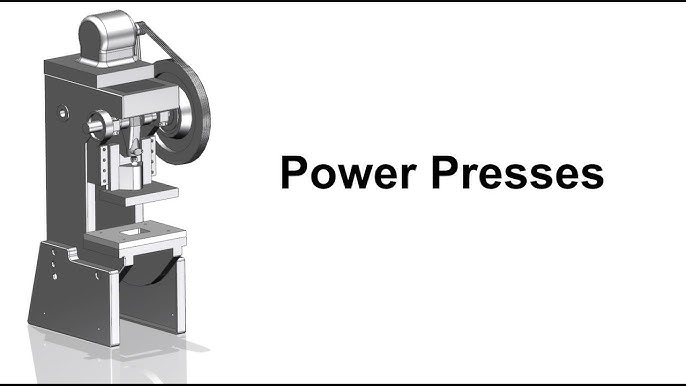

Inside a Press Machine Factory: Production and Assembly Processes

Power press machines are essential tools in modern manufacturing, providing precision, efficiency, and reliability in metal forming, cutting, and shaping operations. Industries such as automotive, electronics, construction, and appliances rely heavily on these machines to produce components in high volumes while maintaining tight tolerances. Understanding the production and assembly processes inside a press machine factory reveals the level of engineering, precision, and quality control required to deliver these complex machines.

The journey of a power press machine begins with careful planning and design. Engineers create detailed CAD models, specifying dimensions, materials, and tolerances for every component. The design stage also includes selecting the type of press—mechanical, hydraulic, pneumatic, or servo-driven—based on operational requirements such as force, speed, and precision. This foundational work ensures that the production process runs smoothly and the final machine meets the intended performance standards.

Visiting a Press Machine Factory provides insight into how these designs are translated into high-precision industrial equipment. The factory floor is organized into sections for material preparation, component machining, assembly, quality inspection, and testing. Each stage follows standardized procedures to maintain consistency and ensure that the machines produced can operate reliably under demanding conditions. Advanced factories also integrate automation, robotics, and digital monitoring systems to streamline production and maintain high levels of precision.

Material Preparation and Component Manufacturing

The first stage in the production process is material preparation. High-strength steels and alloys are commonly used for structural components such as frames, rams, and die supports. Raw materials are inspected for chemical composition, hardness, and tensile strength to ensure compliance with engineering specifications. Cutting, shaping, and heat-treating processes prepare these materials for machining, improving durability and resistance to wear.

Component manufacturing is the next critical step. Precision machining of parts such as gears, flywheels, guides, and hydraulic cylinders is carried out using CNC machines and specialized lathes. Dimensional accuracy and surface finish are closely monitored to maintain consistent performance. Bearings, bushings, and other moving parts are also manufactured to tight tolerances, ensuring smooth operation and reducing friction during the press cycles.

Assembly Process

After machining, components are transferred to the assembly section. The assembly process involves combining the frame, ram, slide, die, gears, and hydraulic or pneumatic systems. Technicians use precision fixtures and jigs to align parts accurately, preventing misalignment that could affect performance or cause premature wear. Bolts and fasteners are torqued to specification, and moving parts are lubricated to ensure smooth operation. Proper assembly is critical to the machine’s stability, precision, and long-term reliability.

Electrical and control systems are integrated during assembly as well. Wiring, sensors, programmable logic controllers (PLCs), and safety mechanisms are installed and tested to ensure proper functionality. Automation features such as robotic feeding systems and servo drives are added when required. This combination of mechanical assembly and electrical integration ensures that the power press machine can operate efficiently and safely in industrial environments.

Quality Control and Inspection

Quality control is a continuous process throughout production and assembly. Each component is inspected for material quality, dimensional accuracy, and surface finish. During assembly, alignment, lubrication, and mechanical movement are tested. After final assembly, the entire machine undergoes functional testing to verify stroke accuracy, force application, cycle speed, and repeatability. Safety systems, including emergency stops, light curtains, and interlocks, are also tested to ensure compliance with industrial safety standards.

Traceability is another critical aspect of quality control. Documentation is maintained for every stage, from raw material inspection to final testing. This information allows the factory to track components, identify potential issues, and implement corrective actions if necessary. Detailed records support continuous improvement initiatives and provide clients with confidence in the machine’s reliability and performance.

Testing and Calibration

Once assembled, power press machines undergo rigorous testing and calibration. Test runs simulate real-world operating conditions, using different materials, thicknesses, and loads. Stroke length, force, and cycle time are measured and adjusted to ensure the machine operates according to specifications. Calibration ensures that the press delivers consistent performance and produces parts with tight tolerances. Machines may also be tested under extended operational cycles to verify durability and identify any potential weaknesses.

Conclusion

Exploring a press machine factory reveals the complex and precise processes required to produce high-quality power press machines. From material preparation and component machining to assembly, quality control, and testing, each stage is carefully managed to ensure reliability, precision, and efficiency. Factories integrate advanced engineering, automation, and rigorous quality checks to deliver machines capable of meeting demanding industrial requirements. By understanding these production and assembly processes, it becomes clear why press machine manufacturers are essential partners for industries relying on consistent, high-volume metalworking operations.