Materials Used in Inflatable Tent Construction

Inflatable tents have become an essential solution for events, outdoor activities, emergency shelters, and promotional campaigns. Their versatility, ease of setup, and portability make them popular across industries. However, the performance, durability, and longevity of an inflatable tent largely depend on the materials used in its construction. Selecting the right materials ensures that the tent can withstand environmental challenges, repeated use, and transportation stress while maintaining its shape and integrity.

Professional Inflatable Tent Manufacturers carefully choose materials that balance durability, flexibility, and affordability. Each component, from the fabric to reinforcements and valves, is selected to meet the specific requirements of the tent’s intended use.

PVC-Coated Polyester Fabric

Polyvinyl chloride (PVC)-coated polyester is one of the most widely used materials in inflatable tent construction. This material combines the strength of polyester with the waterproof and airtight properties of PVC, making it ideal for both indoor and outdoor use. PVC-coated fabrics are resistant to abrasion, moisture, and UV exposure, ensuring longevity even under harsh conditions.

The PVC layer also provides smooth surfaces that are suitable for printing logos, promotional graphics, or branding elements. This makes the material particularly valuable for event tents, trade shows, and promotional installations where visual appeal is important. Its flexibility allows easy folding and transport, while its durability ensures that tents maintain airtight pressure over repeated inflation cycles.

Oxford Fabric with PU Coating

Oxford fabric, commonly coated with polyurethane (PU), is another material frequently used in inflatable tents. It is lighter than PVC-coated fabrics and provides excellent flexibility, making it ideal for tents that require portability and rapid deployment. The PU coating adds waterproofing, enhances resistance to wear and tear, and protects against UV damage.

Oxford fabric is often preferred for camping tents, smaller promotional tents, and temporary shelters where ease of transport and setup is a priority. Its lightweight nature allows manufacturers to produce tents that are manageable by one or two people while still offering adequate durability.

Airtight Laminated Textiles

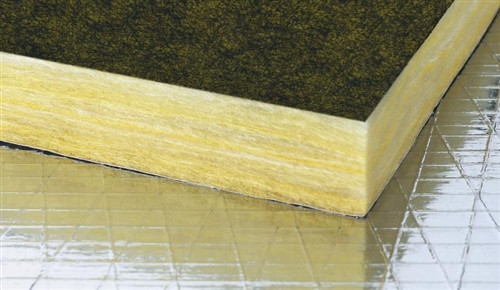

For tents that require exceptional air retention, airtight laminated textiles are used. These multi-layered fabrics are designed to minimize air leakage and maintain pressure over long periods. They combine flexibility with high tensile strength, making them suitable for large inflatable structures, emergency medical tents, or multi-chambered designs.

The lamination process typically fuses multiple layers of polymer films and reinforcing textiles, providing enhanced structural integrity. This ensures that inflatable tents remain stable and maintain their shape even in windy or challenging outdoor conditions.

Reinforcement Materials

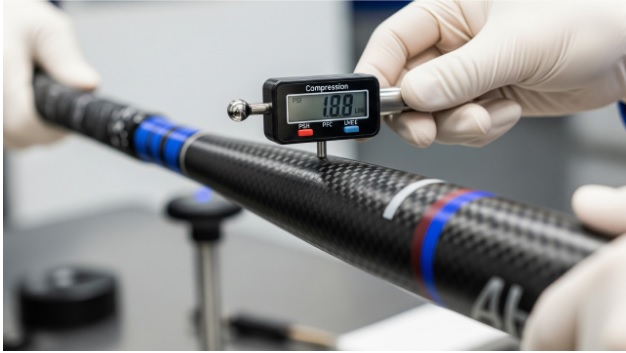

In addition to the primary fabric, inflatable tents rely on reinforcement materials to strengthen critical stress points. These include extra layers of fabric at seams, welded joint tapes, and high-strength stitching. Reinforcement materials prevent tearing, seam failure, and air leaks, especially in high-stress areas like corners, valve connections, and entrance openings.

Reinforced areas are essential for tents used in commercial events, sports activities, or outdoor exhibitions where durability and repeated assembly are expected.

Valves and Airflow Components

While not a fabric, valves and internal airflow components are crucial materials in inflatable tent construction. High-quality valves control inflation and deflation efficiently, maintaining airtightness and structural stability. Internal baffles, air channels, and load-distribution panels help maintain the tent’s shape and prevent sagging. These components are typically made from durable polymers or reinforced plastics to withstand repeated use and high pressure.

Protective Coatings and Treatments

Protective coatings are applied to the primary materials to enhance performance and extend lifespan. Common treatments include UV-resistant coatings, water-repellent finishes, and flame-retardant applications. These coatings protect the tent from sun damage, rain, moisture accumulation, and potential fire hazards. Tents designed for public events, emergency response, or extended outdoor use often incorporate multiple protective treatments to ensure safety and durability.

Environmental and Sustainability Considerations

Modern inflatable tent manufacturers are increasingly considering the environmental impact of the materials they use. Eco-friendly PVC alternatives, recyclable textiles, and low-impact coatings are gaining popularity. These materials provide durability while reducing environmental footprint, making them suitable for clients and organizations focused on sustainable operations.

Conclusion

The materials used in inflatable tent construction determine the tent’s durability, weather resistance, flexibility, and overall performance. From PVC-coated polyester and Oxford fabric to airtight laminated textiles, reinforcements, and protective coatings, each component is carefully selected to meet specific functional and aesthetic requirements. By understanding these materials, buyers and event organizers can choose tents that are reliable, long-lasting, and well-suited for their intended applications. Through careful material selection, inflatable tent manufacturers ensure that each tent delivers safety, performance, and visual appeal for events, outdoor activities, and emergency scenarios.