Overview of Polyurethane Foaming Machine Manufacturers and Their Capabilities

Polyurethane (PU) foam is an essential material used across industries such as automotive, furniture, construction, refrigeration, and packaging. The production of high-quality foam depends heavily on the performance and reliability of specialized machinery. Polyurethane foaming machines are designed to mix, meter, and dispense chemical components with precision, producing foam that meets strict standards for density, elasticity, and durability. The manufacturers behind these machines play a crucial role in advancing foam production technology and enabling efficient, consistent output.

Reputable Polyurethane Foaming Machine Manufacturers offer a wide range of capabilities to meet diverse industrial requirements. Their expertise extends beyond basic machine production to include design, customization, automation integration, quality control, and after-sales support. By combining engineering excellence with technological innovation, these manufacturers provide equipment that allows companies to optimize production, reduce waste, and maintain high product quality across various applications.

Types of Machines Produced

Polyurethane foaming machine manufacturers develop equipment to meet different production needs, primarily categorized by pressure levels and production methods:

- High-Pressure Foaming Machines

These machines use high-pressure mixing systems to blend polyol and isocyanate components with precision. They are widely used in automotive seating, appliance insulation, and other applications requiring dense, uniform foam. High-pressure systems provide consistent foam quality even in large-scale production. - Low-Pressure Foaming Machines

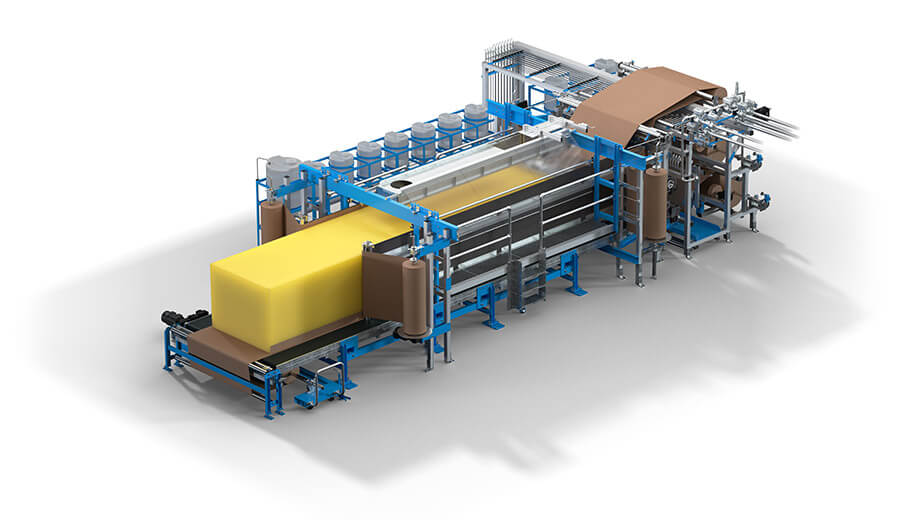

Low-pressure machines are suitable for smaller production volumes or applications requiring less complex mixing. Commonly used in furniture cushions, packaging materials, and molded parts, they offer cost efficiency, ease of maintenance, and reliable output for medium-scale operations. - Continuous Foaming Machines

Designed for slabstock foam production, continuous machines operate non-stop to create large foam blocks, which are later cut into sheets or custom shapes. This type of equipment is essential for mattress production, upholstery, and industrial insulation materials. - Spray Foam Machines

Spray foam equipment is specialized for construction and insulation applications. These machines allow contractors to apply expanding foam directly to surfaces, creating effective thermal and acoustic barriers.

Automation and Digital Integration

Modern polyurethane foaming machine manufacturers increasingly focus on automation to improve efficiency and reduce human error. Automated features include programmable logic controllers (PLCs), touchscreen interfaces, and real-time monitoring systems that control chemical metering, mixing, and injection processes. These systems enable operators to maintain precise ratios, optimize cycle times, and track production data for analysis and quality assurance.

Some manufacturers also integrate IoT-enabled sensors and smart diagnostics, allowing remote monitoring and predictive maintenance. These capabilities help detect anomalies early, reduce downtime, and ensure consistent foam quality across multiple production lines.

Customization and Specialized Solutions

Another key capability of polyurethane foaming machine manufacturers is their ability to provide customized solutions tailored to client requirements. This may include:

- Custom mold designs for complex shapes

- Adjustable output capacities for variable production volumes

- Specialized machines for integral skin foam or elastomer casting

- Configurations optimized for specific raw materials or foam formulations

Customization ensures that industrial clients can achieve the exact foam properties required for their products while maintaining efficient production workflows.

Quality Control and Safety Standards

Quality control is central to the manufacturing process. Manufacturers implement rigorous inspection, calibration, and testing procedures to ensure machines operate reliably. Key quality control measures include:

- Testing metering accuracy and mixing consistency

- Verifying pressure and flow stability

- Inspecting mechanical components for durability and corrosion resistance

- Conducting safety tests, including emergency shut-offs and pressure relief mechanisms

Compliance with international safety and environmental standards is also emphasized, protecting operators and ensuring that machines meet regulatory requirements.

After-Sales Support and Maintenance

Polyurethane foaming machine manufacturers provide comprehensive maintenance support, which is crucial for long-term operational efficiency. Services often include preventive maintenance schedules, spare parts supply, on-site technical assistance, and operator training. Maintenance support helps prevent downtime, extend the life of the equipment, and maintain consistent foam quality over time.

Remote diagnostics and digital monitoring capabilities further enhance support by allowing manufacturers to provide timely guidance and troubleshoot issues without the need for immediate on-site visits. This combination of service and technology ensures that clients can operate their production lines with confidence.

Global Capabilities and Industry Reach

Manufacturers of polyurethane foaming machines operate globally, serving a variety of industries and production scales. European manufacturers often excel in automation and precision engineering, while Asian suppliers provide scalable, cost-effective solutions. North American companies combine technological innovation with strong customer support and compliance with environmental standards. This global diversity allows clients to select machines tailored to their production requirements, budget, and long-term goals.

Conclusion

Polyurethane foaming machine manufacturers play a critical role in supporting modern industrial production by offering versatile, high-precision, and reliable equipment. Their capabilities extend from high-pressure and low-pressure machines to fully automated, custom, and specialized solutions. With a focus on quality control, safety, maintenance support, and technological innovation, these manufacturers ensure consistent foam production, operational efficiency, and long-term reliability. By partnering with a reputable manufacturer, companies can optimize their PU foam processes and meet the exacting standards of their industries.