Reliability Testing of the Best RF Connectors

RF connectors are vital components in high-frequency electronic systems, providing reliable signal transmission across a wide range of applications, including telecommunications, aerospace, defense, medical devices, and industrial electronics. The reliability of these connectors is essential, as failures can lead to signal degradation, system downtime, or even critical safety issues. To ensure optimal performance, the best RF connectors undergo rigorous reliability testing throughout their design and manufacturing processes.

Importance of Reliability Testing

Reliability testing is a fundamental step in assessing the durability and performance of RF connectors under real-world conditions. These tests evaluate how connectors respond to mechanical, electrical, and environmental stresses that they may encounter during operation. Testing ensures that connectors meet or exceed industry standards and can maintain signal integrity over time.

Reliable connectors are particularly crucial for mission-critical applications such as aerospace communication systems, military electronics, and medical equipment. Engaging with a supplier that provides the Best RF Connectors guarantees access to components that have undergone stringent reliability testing, ensuring consistent performance in demanding environments.

Mechanical Reliability Testing

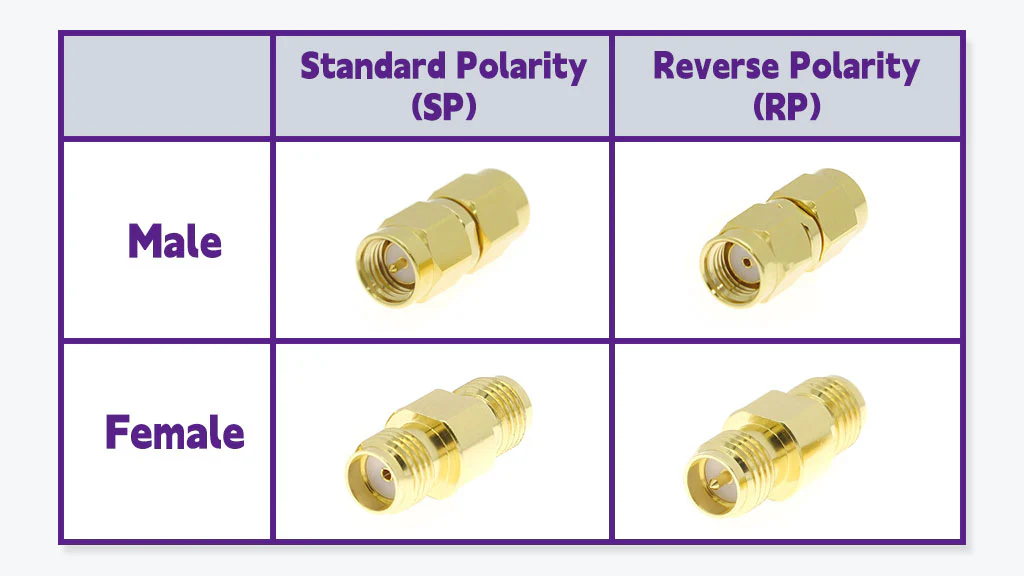

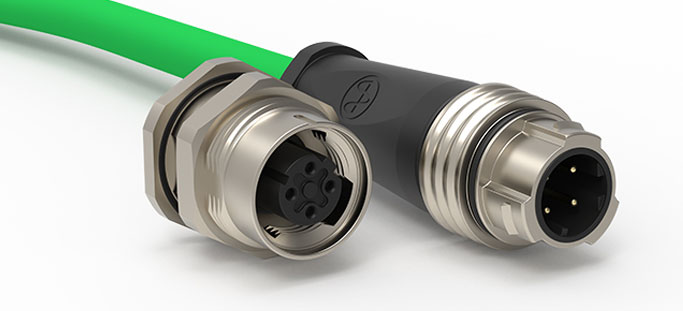

Mechanical testing assesses the physical robustness of RF connectors. This includes evaluating the performance of connectors under repeated mating and unmating cycles, which simulates typical usage over the product’s lifetime. Threaded connectors, like SMA and TNC types, are tested for torque tolerance and mechanical stability, ensuring they maintain secure connections without loosening over time. Snap-on connectors, such as SMB and MCX types, are tested for durability during frequent mating cycles, ensuring the connectors maintain proper contact and low insertion loss.

Vibration and shock testing are also crucial for connectors used in aerospace, automotive, or industrial applications. These tests expose connectors to vibrations and mechanical shocks to confirm that they can withstand transportation, installation, and operational stresses without compromising performance. High-quality RF connectors must maintain electrical integrity and mechanical alignment under these challenging conditions.

Electrical Performance Testing

Electrical reliability testing ensures that RF connectors maintain signal integrity across their intended frequency range. Key parameters include insertion loss, return loss, voltage standing wave ratio (VSWR), and impedance matching. Connectors are tested under varying signal frequencies and power levels to verify that they deliver consistent performance in real-world applications.

High-power RF connectors undergo additional testing to confirm their ability to handle thermal and electrical stress without degradation. Testing under extreme current or voltage conditions helps ensure that the connector will not overheat, degrade, or cause signal disruption during operation. Accurate and consistent electrical performance is critical for applications like high-speed communication systems and precision instrumentation.

Environmental Testing

Environmental testing evaluates how RF connectors perform under harsh conditions such as temperature extremes, humidity, and exposure to dust, moisture, or corrosive substances. Temperature cycling tests expose connectors to repeated high and low temperatures to simulate operational conditions in outdoor or extreme environments. Humidity and corrosion tests ensure that connectors remain functional in damp or corrosive conditions, which is especially important for outdoor antennas, satellite systems, and industrial electronics.

Sealed or ruggedized connectors undergo additional environmental testing to validate their weather resistance. Salt spray tests, UV exposure, and contamination testing verify that connectors maintain reliability in marine, desert, or high-altitude environments. These tests provide confidence that connectors will continue to perform consistently throughout their service life.

Lifecycle and Accelerated Aging Tests

Lifecycle testing and accelerated aging tests simulate long-term usage in a shorter timeframe, helping engineers predict the lifespan and durability of RF connectors. These tests involve repeated mechanical, electrical, and environmental stresses to identify potential failure modes before the product reaches the market. By simulating years of operation in weeks or months, suppliers can ensure that connectors meet durability expectations and provide long-term reliability.

Compliance with Industry Standards

Reliability testing also ensures that RF connectors comply with industry standards such as MIL-STD, IEC, RoHS, and ISO certifications. Compliance demonstrates that connectors meet rigorous requirements for performance, safety, and environmental responsibility. Working with suppliers that prioritize adherence to these standards ensures that the connectors used in critical systems are dependable and meet regulatory expectations.

Conclusion

Reliability testing is an essential aspect of producing the best RF connectors, ensuring that they perform consistently under mechanical, electrical, and environmental stresses. Mechanical durability, electrical performance, environmental resistance, lifecycle testing, and compliance with industry standards all contribute to the overall reliability of connectors.

By choosing a supplier that offers the Best RF Connectors, businesses can access components that have undergone comprehensive testing, providing confidence in their long-term performance. Reliable RF connectors are crucial for maintaining signal integrity, minimizing system downtime, and supporting mission-critical applications across diverse industries.